Edward Davey, UK’s Secretary of State for Energy & Climate Change announced funding for the next stage of Shell’s Peterhead CCS project in February 2014.

The FEED study will allow a detailed programme of engineering, planning and financial work to finalise and de-risk all aspects of the proposal ahead of taking the final investment decisions.

Peterhead power station

The Peterhead power station is a Combined Cycle Gas Turbines (CCGT) station owned and operated by Scottish and Southern Energy near Peterhead in Aberdeenshire.

Peterhead is situated on the coast, and lies close to available pipelines that can safely transport CO2. The Goldeneye depleted gas field is about 100km offshore in the North Sea.

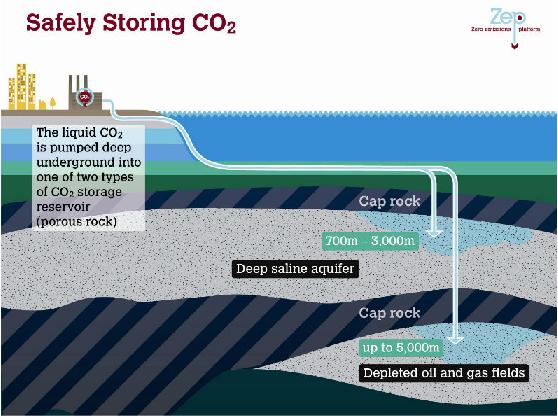

The Project will investigate capturing more than 85% of CO2 emissions that would otherwise be emitted to the air; this CO2 will then be transported by pipeline to the Goldeneye platform in the North Sea for storage in a depleted gas reservoir about 2.5km below the sea bed.

The UK and CCS

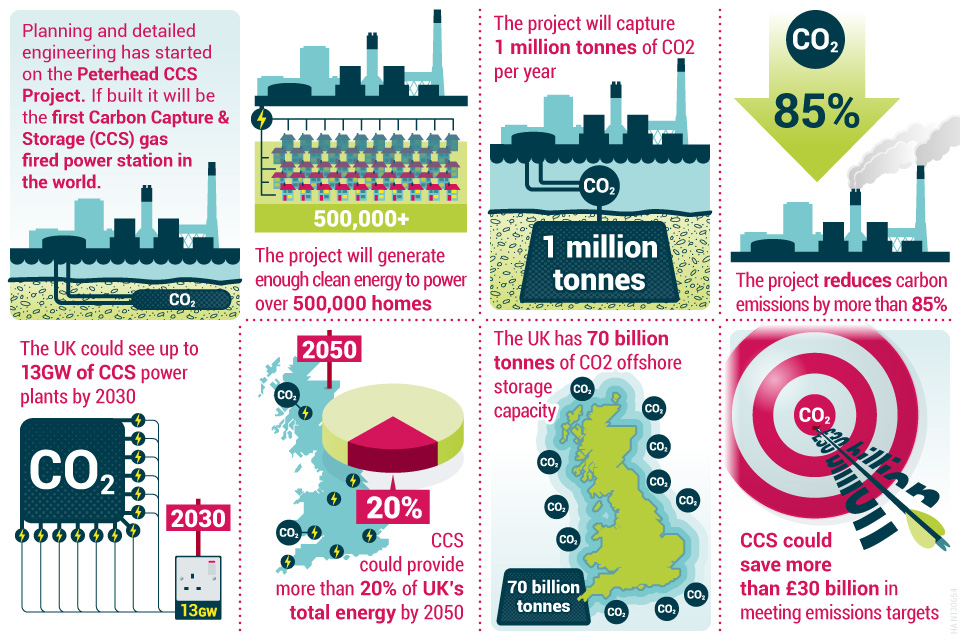

The UK is a global leader in CCS, progressing the next stage of the world’s first gas CCS project which if built could capture 1 million tonnes of CO2 each year and provide clean electricity for more than 500,000 homes.

In December 2013, the Secretary of State announced support for the White Rose CCS project to develop a new state-of-the-art clean coal power plant with full carbon capture and storage.

The UK Government is investing around £100m in the White Rose and Peterhead CCS projects.

By 2050, CCS could provide more than 20% of the UK’s electricity and save UK more than £30bn a year in meeting our climate targets.

The government is working with industry to create a new cost-competitive CCS industry in the 2020s. UK’s support for the development of CCS includes:

- a £1 billion commercialisation competition to support practical experience in the design, construction and operation of commercial-scale CCS

- a £125 million, 4-year co-ordinated research, development and innovation programme

- reform of the UK electricity market so CCS will be able to compete with other low-carbon energy sources

How CCS works

Once developed at scale CCS could:

- allow the safe removal and permanent storage of carbon dioxide emissions from coal and gas power stations

- remove and permanently store emissions from large industrial sources such as steel or cement factories

The technologies used in CCS (capture, transport and storage) aren’t particularly new or unique. They have been used for many years individually (notably in the oil and chemical sectors) but to bring down costs and allow CCS to be more widely used, the full chain of capture, transport and storage needs to be built and operated on a commercial. Boundary Dam in Canada is likely to be the first coal power station in the world to operate with commercial scale CCS. The Peterhead CCS Project could be the first gas power station in the world.

- CBCSD and Members Participated and Suggested on the Project for Technical Regulation on Low-carbon Pilot Community

- CBCSD and Members Participated in the APEC Cooperation Network Construction Forum of Green Supply Chain

- Calculation Method of CO2 Emissions in Petroleum and Natural Gas Exploitation Enterprises & Calculation Method of CO2 Emissions in Water Network of Chemical Enterprises

- CBCSD Attended the Workshop for Environmental Protection and Sustainable Development and Delivered Introductions

- WBCSD: Tackling the Challenge, How to Make Informed Choices on Forest Product?

- The National New-Type Urbanization Plan Released, Board Members of CBCSD Help the Sustainable Development of Cities

- Board members of CBCSD Actively Participated in the Carbon Trading and International Climate Change Process

- Two industrial Standards Compiled by CBCSD Passed Examination

- Widespread Use of the Achievements Businesses Energy Saving and Greenhouse Gas Management

- CBCSD held Chemical industry enterprise value chain (range 3) greenhouse gas emissions, accounting and reporting guidelines